PREMIERTM Electrically Conductive Plastics

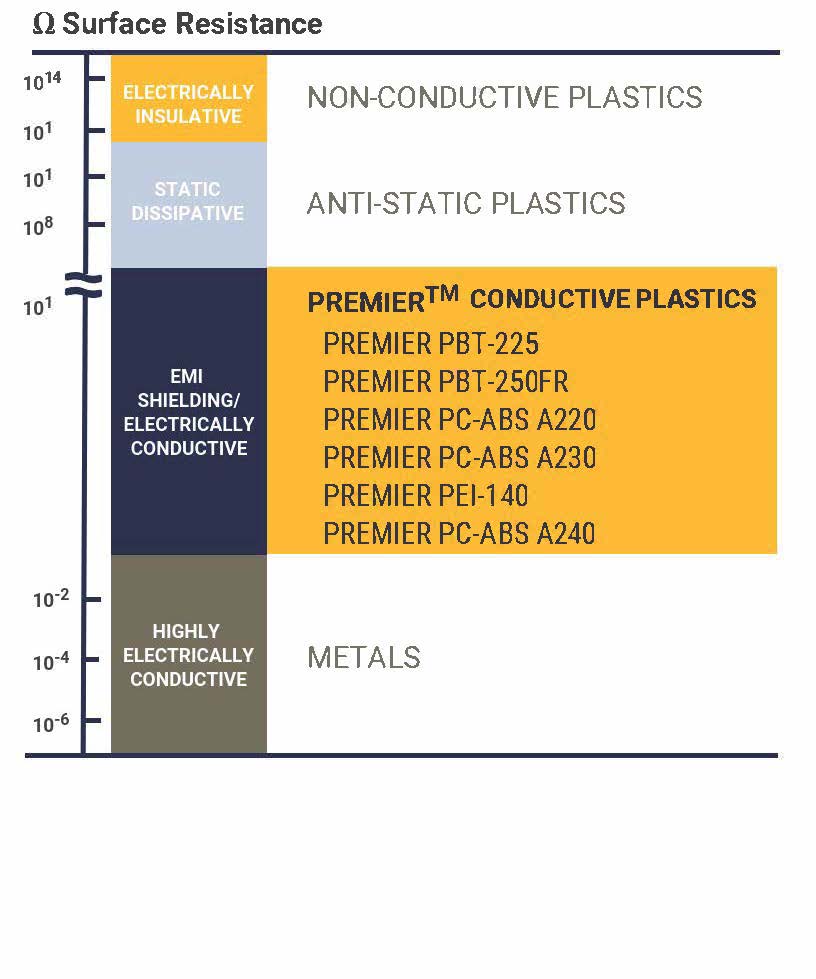

Unlike normal plastics, electrically conductive plastics have the ability to conduct electricity -- providing “immunity” for sensitive components from incoming electromagnetic interference (EMI) and/or prevent excessive emissions of EMI to other susceptible equipment.

Product designers and engineers are discovering the unique advantages of electrically conductive plastics compared to traditional metals – such as weight reduction, cost reductions, elimination of secondary manufacturing steps – all resulting in leaner supply chains and better products.

Why Conductive Plastics?

Parker Chomerics PREMIERTM ‘single pellet’ electrically conductive plastic pellets offer superior performance and consistency when compared to many conductive plastic materials. The primary advantage of PREMIER is the use of pultrusion compounding to ensure uniform amounts of conductive filler are within each pellet.

Our PREMIER electrically conductive plastics are manufactured as single pellet formulations, which ensures the most reliable, consistent shielding of molded products.

Single pellet or homogeneous products are far superior to multi-pellet blends (also called dry blends or salt-and-pepper blends) that use pellets from different compounds randomly mixed together.

EMI Shielding Consistency from Part-to-Part

Conductive plastic single pellet performance benefits are easily demonstrated when shielding performance is compared between dry blend materials and PREMIER single pellets in capability studies. Our single pellet materials prevent the risk of poor EMI shielding – and this avoids potential failure in the field.

✔ PREMIER SINGLE PELLETS

Single electrically conductive fiber in every pellet leads to consistent EMI shielding performance.

✘ MULTI-PELLET BLENDS

Non-homogenous mix of conductive slugs and plastic pellets leads to uneven EMI shielding performance.

Electrically Conductive Plastic Options

No Packaging Size Limitations

Dry blends (that use multiple pellet mixtures) have packaging limitations – they are sold only in smaller bags or containers, and carry the risk of the heavier pellets settling during transportation.

When settling occurs, it results in inconsistency in shielding and mechanical performance. Large volume programs can save significant labor hours by using single pellet products such as PREMIER.

Up to 75% Less Mass

Our conductive plastics have a density of 1.2 to 1.4 g/cc, which is nearly one-half the density of aluminum (2.7 g/cc).

Conductive plastics offer light weight, coupled with the ability to mold thinner walls, allowing parts to weigh up to 75% less.

PBT and PEI CONDUCTIVE PLASTIC GRADES

PBT is known for its excellent chemical resistance thereby making it an ideal material for environments that have exposure to automotive type fluids (gasoline, motor oil, glycol 50/50 mix, brake and transmission fluids).

PEI (aka “Ultem”) polymer material is UL V-0 rated down to 1.8 mm wall thickness and has a special blend of conductive elements. This material meets the Boeing 7238 smoke density rating of MAX 110 Ds with 3.0 mm @ 4 minutes.

PBT-225

Polybutylene terephthalate

50-75 dB shielding

Hydrolysis resistant

75° C

UL 94 HB

Carbon granules,

stainless steel

PBT-250-FR

Polybutylene terephthalate

50-75 dB shielding

Flame retardant

75° C

UL 94 5VA

Carbon fiber,

stainless steel

PEI-140

Polyetherimide

50-75 dB shielding

Defense/aero grade

170° C

UL 94 V-0

Carbon fiber, carbon granules,

stainless steel

PC-ABS GENERAL PURPOSE GRADES (HT)

Provides up to 85° C continuous use temperature rating and is the most cost-effective grade of our Nickel-Plated carbon fiber and granule filled polymers. A230-HTHF and A240-HTHF versions use “HF” (Hybrid Filler) granular graphite to improve cost and minimize post mold warpage.

A230-HTHF

Polycarbonate ABS

50-75 dB shielding

Economical

85° C

Carbon fiber/granular filler

PC-ABS SUPER TOUGH AND ELEVATED TEMPERATURE GRADES (ST)

Provides up to 105° C continuous use temperature rating and the lowest possible surface resistivity for excellent grounding properties. Filled with nickel-plated carbon fiber exclusively to maximize conductive properties of the molded product.

PC-ABS FLAME RETARDANT GRADES (FR)

UL V-0 rated to 1.5 millimeters wall thickness and provides up to 70° C continuous use. Uses Nickel-Plated carbon fiber and granular fillers. Moderate and high filled versions use “HF” (Hybrid Filler) granular graphite to improve cost and minimize post mold warpage.

A220-FR

Polycarbonate ABS

40-60 dB shielding

Flame retardant

70° C

UL 94 V-0

Carbon fiber filler

A230-FRHF

Polycarbonate ABS

50-75 dB shielding

Flame retardant

70° C

UL 94 V-0

Carbon fiber and carbon granular fillers

A240-FRHF

Polycarbonate ABS

75-90 dB shielding

Flame retardant

70° C

UL 94 V-0

Carbon fiber and carbon granular fillers

ENGINEERING AND PRODUCT SUPPORT

Our experienced engineers are available to help with optimal material selection and manufacturing strategies for each project. This includes support to ensure properly matched EMI gaskets, product design strategies, tooling, and other needs.

CONTACT US

We're here to help.

Buy Electrically Conductive Plastic Test Boxes

Test boxes are available as 100mm x 140mm x 85mm in the below materials and give engineers the ability to evaluate our electrically conductive plastic materials in a representative format similar to their end application. All test boxes come with a gasket and are ready for your components.

PREMIER PBT-225

Polybutylene terephthalate

50-75 dB shielding

Hydrolysis resistant

75° C rating

UL 94-HB

Our products are used in a wide rage of industries.

EMC Considerations for Product Designers and Engineers

If you are a product designer or engineer who wants to know about the many solutions for electrmagnetic interference (EMI) shielding or simply wanted a refresher on the basics of EMC, this webinar is for you. You will learn the theory behind EMC, the products available to meet EMC regulations, the basics of testing for EMI/RF compliance, and hear about real-world application examples.

Can't find what you're looking for? Talk to one of our experts.