Power Generation that Never Stops

Parker SensoNODE™ Gold Sensors and Voice of the Machine™ Software Prevents Unexpected Downtime

What if your operations and maintenance teams could know in advance that your power generation equipment was going to fail?

If your machines are equipped with Parker’s SensoNODE Gold Sensors and Voice of the Machine condition monitoring software, the power to eliminate impending downtime is in your hands.

Experience the Power of SensoNODE

In the power generation industry, having a condition monitoring system capable of collecting and distributing key knowledge about machine health is critical for maximizing output and efficiency. That’s because even the slightest operational interruption can have significant consequences.

From gas and steam turbines to water pumps, plant maintenance teams and reliability engineers depend on condition monitoring to track vibration, temperature, pressure, and humidity to establish a baseline, trend, and early warning/detection of machinery health.

SensoNODE Gold Sensors and Voice of the Machine Software allow these variables to be monitored anytime and from anywhere technicians have an internet connection.

Parker’s condition monitoring solution helps power generation companies keep production flowing by monitoring critical assets to identify issues that could cause unplanned downtime and impact production. It also extends the life of machines and equipment and makes maintenance more efficient.

To learn more about how SensoNODE Gold Sensors and Voice of the Machine Software can help your operation prevent equipment failure before it happens, contact a Product Specialist.

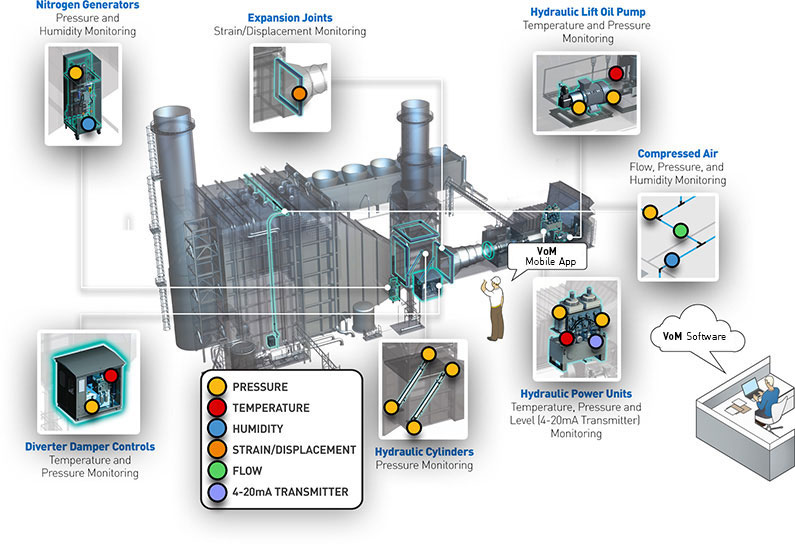

There are several points of interest throughout a power generation plant that need to be tracked for a condition monitoring solution to be effective.

Power Generation Applications

There are several key pieces of equipment throughout a power generation plant that SensoNODE can monitor for potential issues, including:

- Monitor temperature of turbine components

- Hydraulic lift pumps

- Hydraulic power units

- Diverter damper controls

- Monitor vibration for bearings for large rollers

- Monitor hydraulic oil temperature

- Monitor pressure changes of turbine components

- Hydraulic lift pumps

- Hydraulic lift pumps, power units, and cylinders

- Diverter damper controls

- Nitrogen generators

- Monitor humidity—in-line and ambient levels

- Track gradual trends of increased facility humidity

- Better diagnose in-line issues

- Closely monitor nitrogen generator levels

Users can also take advantage of Voice of the Machine’s historic tracking ability to review trends over time to improve decision-making and optimize existing infrastructure.

©2023 Parker Hannifin Corporation | Quick Coupling Division | Privacy Policy