What are Helac Hydraulic Rotary Actuators

The Cylinder Division specializes in the design, production and development of helical hydraulic rotary actuators for the worldwide mobile hydraulics market. Helac rotary actuators are powerful and compact helical rotary actuators designed to replace multiple components and function as a rotating device, mounting bracket and bearing all-in-one. Helac actuators are unique in their inherent load bearing capacity, extreme shock resistance and rugged durability, providing cost effective solutions for a broad range of applications that demand high performance.

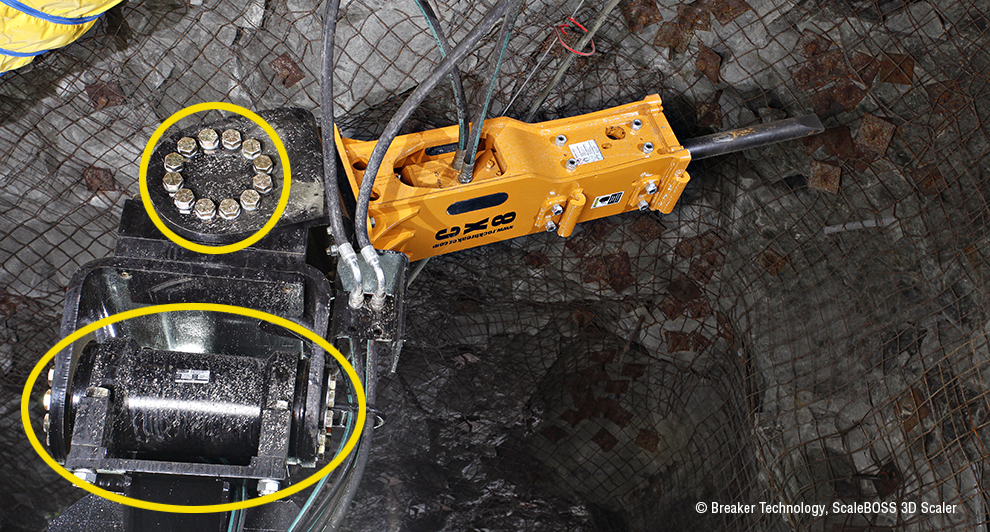

Helac rotary actuators are used in agriculture, construction, energy, marine, material handling, military, mining, and waste/recycling industries across the world. The L-Series actuators are heavy duty 180 degree and 360 degree rotary actuators designed for applications that require high load bearing capacity. The T-Series actuators are ideal for high torque applications where torque generation and higher cycle rates are the primary requirements.

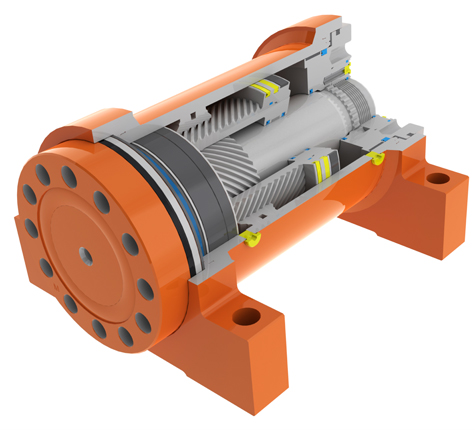

How does a Helac Hydraulic Rotary Actuator Work

Helac’s innovative sliding-spline technology converts linear piston motion into powerful shaft rotation. Each hydraulic rotary actuator is comprised of a housing and two moving parts — the central shaft and piston. Helical spline teeth on the shaft engage matching teeth on the piston’s inside diameter. A second set of helical splines on the piston’s outside diameter mesh with the gear in the housing. In the Starting Position, the piston is completely bottomed out. Bars indicate starting positions of piston and shaft. The housing with integral gear remains stationary. In the Ending Position, when hydraulic pressure is applied to the piston, it moves axially, while the helical gearing causes the piston and shaft to rotate simultaneously. Applying pressure to the opposite port will return the piston and shaft to their original starting positions.

Helac Hydraulic Rotary Actuator Catalog

Download the Helac rotary actuator catalog to see how this innovative technology works, to learn about all the benefits of Helac actuators and view specs and sizes of available actuators.

Helac Rotary Actuator Success Story

Lifters Designed With Rotary Actuators Dump

Waste More Effectively.