CASE STUDY

High Performing Thermal Interface Material Required for Automotive Audio Hardware Manufacturer

A premium automotive infotainment and entertainment system manufacturer required a high performing thermal interface material capable of filling five locations on the PCB, each having different footprints and gap heights.

THE CHALLENGE

A premium automotive system manufacturer required a high performing thermal interface material (TIM) for their infotainment and entertainment module. This TIM needed to be capable of filling five locations on their PCB, each having different footprints and gap heights. The customer needed to determine the material and the correct amount to dispense in each location, as well as equipment to best dispense in the high-volume market. Compounding the issue, the material would undergo a solder reflow process which would reach temperatures as high as 245°C. The upper operating temperature for TC50 (and silicone-based gels) is 200°C.

DESIGN REQUIREMENTS

- Provide proper thermal dissipation

- Low stress on components

- Simple to dispense

- Survive the solder reflow process

KEY CUSTOMER REQUIREMENTS

- High thermal conductivity dispensable (5 W/m-K)

- Proper adhesion to PCB for reliability

- Dispense solution (vendor, equipment)

- No change in thermal or mechanical properties after exposed to 245°C per solder reflow process (1 minute exposure)

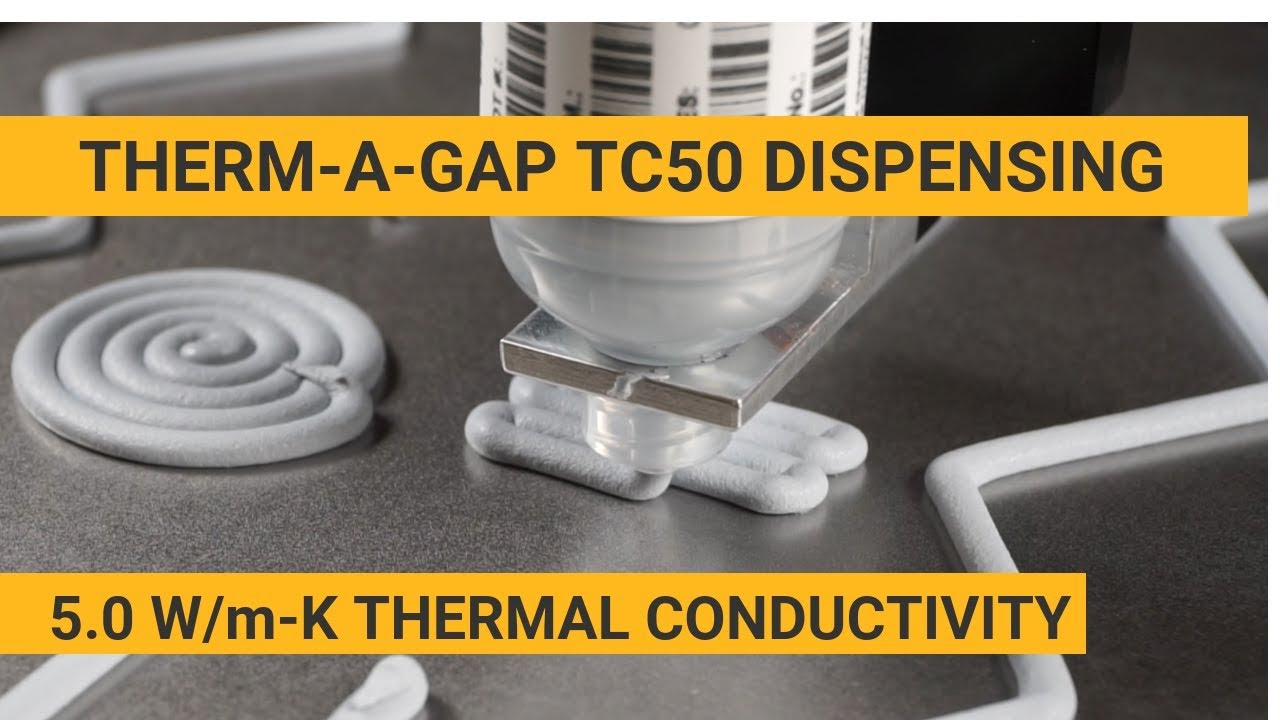

3D printed prototype PCB for testing, next to another 3D printed model with THERM-A-GAP TC50 dispensed and compressed.

THE SOLUTION

The customer shared a PCB with Parker Chomerics, which was then replicated by our experienced Applications Engineering team using an in-house 3D printer.

The 3D printed prototype parts enhanced the five locations for dispensing, so that they could be correctly identified for precise dispense location.

Utilizing a dispensing system from PVA at our state-of-the-art applications engineering lab in Woburn, MA, THERM-A-GAP TC50 was selected for its high thermal conductivity and dispensed onto the 3D printed parts for trials and capabilities. The prototype parts were successful in representing the actual PCB.

The customer visited the applications lab to view the dispensing and determined that THERM-A-GAP TC50, along with the PVA equipment, would be ideal for their high-volume program.

To determine how the extreme temperature conditions would affect THERM-A-GAP TC50, experimentation was run to study the thermal and mechanical properties on the thermal compound. THERM-A-GAP TC50 samples were exposed to the 245°C solder reflow process, and the results concluded that the TI and viscosity did not deviate over the extended time exposure.

CONCLUSION

Parker Chomerics selected THERM-A-GAP TC50 due to its combination of high thermal performance as well as its ability to be dispensed onto the complex parts with ease. With our application engineering team's expertise in 3D printing prototype parts, along with our engineering lab which customers are encouraged to utilize, allowed the Parker Chomerics team to successfully provide a full solution to the customer within one week of receiving the customer's parts for trials.

After sharing the experimental results with the customer, Parker Chomerics and the customer tested an entire assembly (PCB board with THERM-A-GAP TC50 and a cover) in the actual solder reflow profile. It was found that the material maintained its rheological structure along with its intended thermal properties.

THERM-A-GAP TC50

High Performance Dispensable Thermal Putty

Parker Chomerics THERM-A-GAP™ TC50 is a single-component, fully cured, dispensable putty with 5.0 W/m-K Thermal Conductivity. Learn More.

We’re constantly innovating in our drive to create the most advanced EV solutions.

2023 Thermal Interface Material Innovations

Over the last year, Parker Chomerics has developed new, state of the art thermal interface materials, or TIMs, for use across industries and applications. These novel products continue to expand the portfolio of high performance, high reliability thermal gap pads and dispensable thermal gels.

Can't find what you're looking for? Talk to one of our experts.