CASE STUDY

High Performing Thermal Interface Material Required for Automotive Safety Module Manufacturer

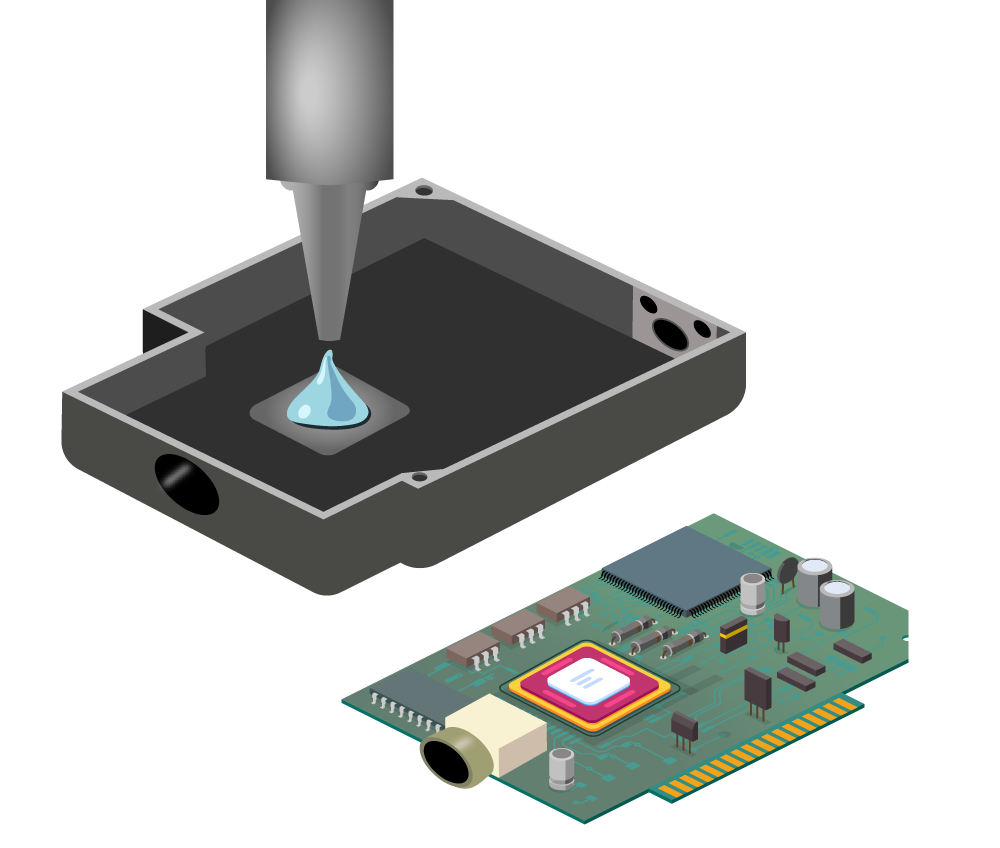

A global automotive supplier required a high performing, robotically dispensed, thermal interface material for an automotive ADAS module.

THE CHALLENGE

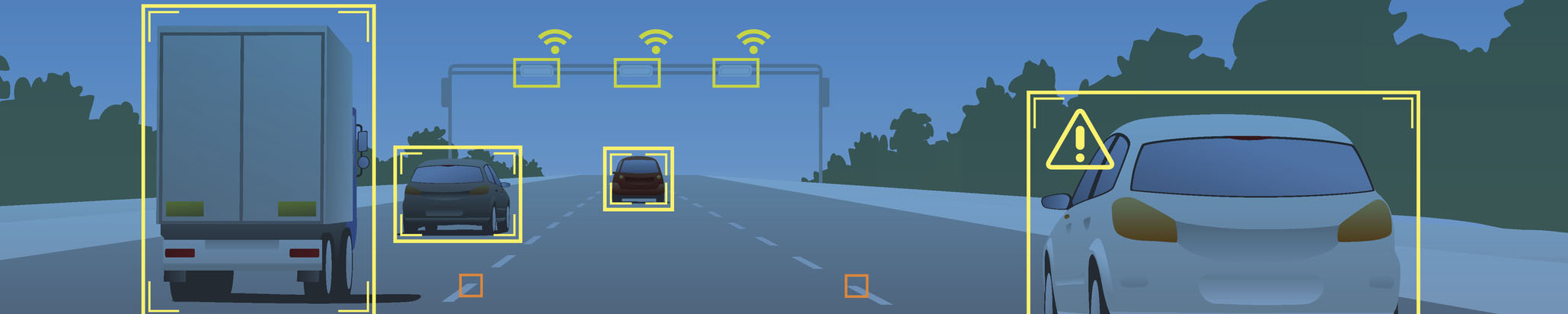

As automotive vehicles continue to rely more on advanced driver-assistance systems (ADAS), more automotive camera and motion sensor companies will need to expand their technologies to meet stringent government requirements. For a new module platform, a premium automotive camera company partnered with Parker Chomerics for a high preforming thermal interface material.

The manufacturing company preferred thermal pads over thermal dispensables due to previous negative experiences with dispensing, however at this high of a manufacturing volume pads were not a feasible option. In addition, the thermal material needed to be higher in thermals than they typically used and needed to be dispensed at a higher rate.

DESIGN REQUIREMENTS

- Soft compression

- Ease of dispensing

- Flow rate suited for high volume manufacturing

KEY CUSTOMER REQUIREMENTS

- Material must be visible to optical cameras on the assembly line

- Thermal conductivity over 3 W/m-K

THE SOLUTION

Application engineers at Parker Chomerics worked with a model of the housing component for the camera to determine the ideal material and amount for each dispensing location. Using the PVA machine, Parker Chomerics determined the proper “wet out” of the module. After, the automotive camera manufacturer ran battery tests to ensure the amount of material was adequate to the heat and would not damage the printed circuit board (PCB) during assembly.

In addition, the flow rate of the thermal interface material was a critical consideration that contributed to the final decision as it had to be high enough to accommodate high volume manufacturing.

CONCLUSION

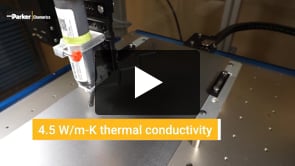

After extensive testing and trials, it was determined that Parker Chomerics THERM-A-GAP GEL 45 was the best thermal interface material for the camera module. GEL 45 has a high flow rate suited for high volume manufacturing (55 grams/min), a thermal conductivity of 4.5 W/m-K, and is black so it would be able to be seen by optical cameras on the assembly line.

THERM-A-GAP GEL 45

High Performance Fully Cured Dispensable GEL

Parker Chomerics THERM-A-GAP™ Gel 45 is a single-component, fully cured, dispensable gel with 4.5 W/m-K Thermal Conductivity. Learn More.

We’re constantly innovating in our drive to create the most advanced EV solutions.

2023 Thermal Interface Material Innovations

Over the last year, Parker Chomerics has developed new, state of the art thermal interface materials, or TIMs, for use across industries and applications. These novel products continue to expand the portfolio of high performance, high reliability thermal gap pads and dispensable thermal gels.

Can't find what you're looking for? Talk to one of our experts.