Parker LM-Pro

Linear Motor Proportional Valve

Features:

- Unparalleled Controllable Range: LM-Pro enables accurate low and high flow rate control

- Low Power: Typical operation under 2W

- Long Life: Tested to 100 million cycles

- Impressive Package Size: Light weight, highest flow range in its class

- Simple Integration: Face mount porting and optional filter reduces manifold complexity

Fast Turn Around Evaluation Samples

Fill out the form below to request a sample

Best in class performance

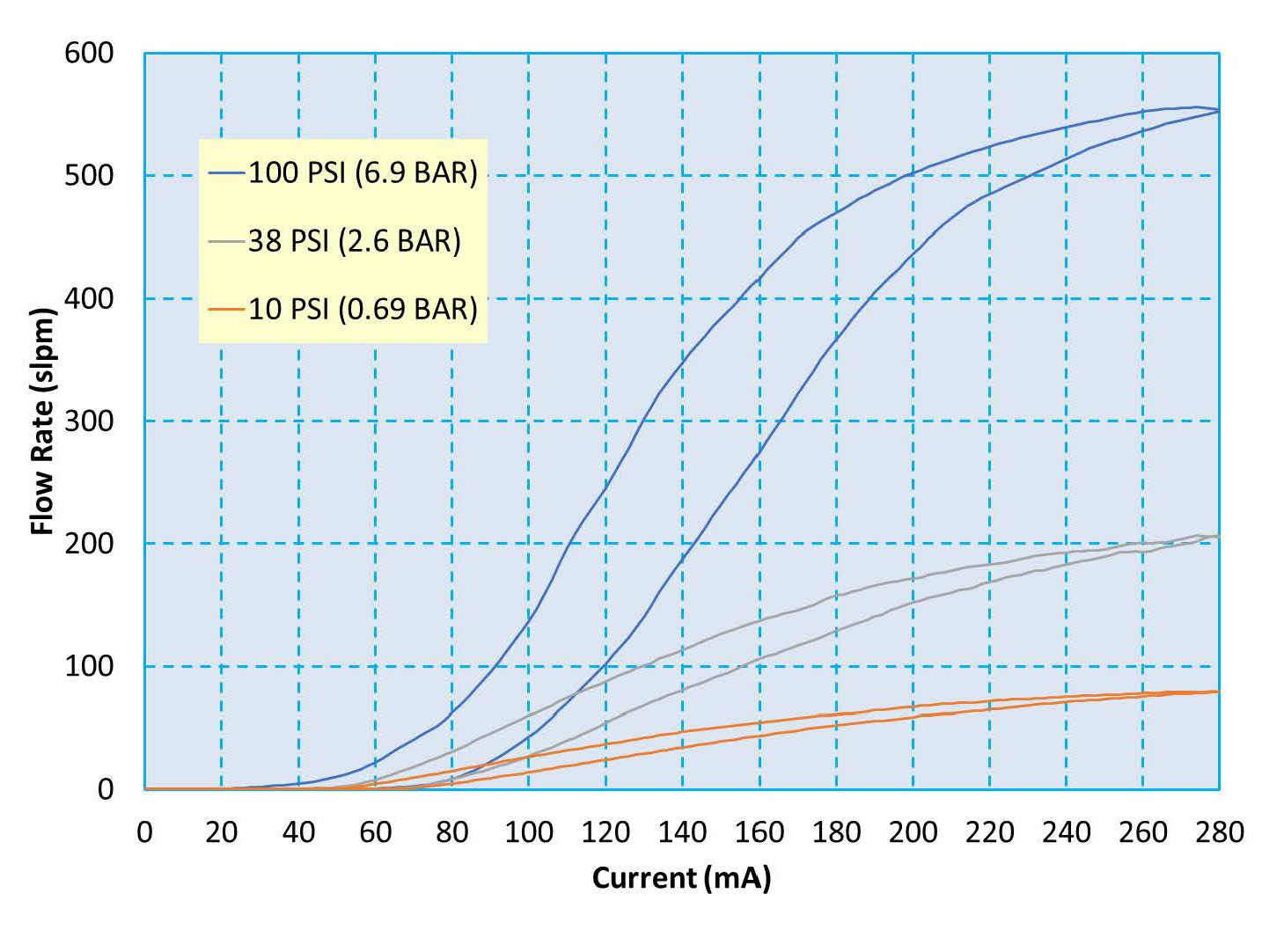

LM-Pro Model 2

Typical Air Flow with 12 VDC Coil

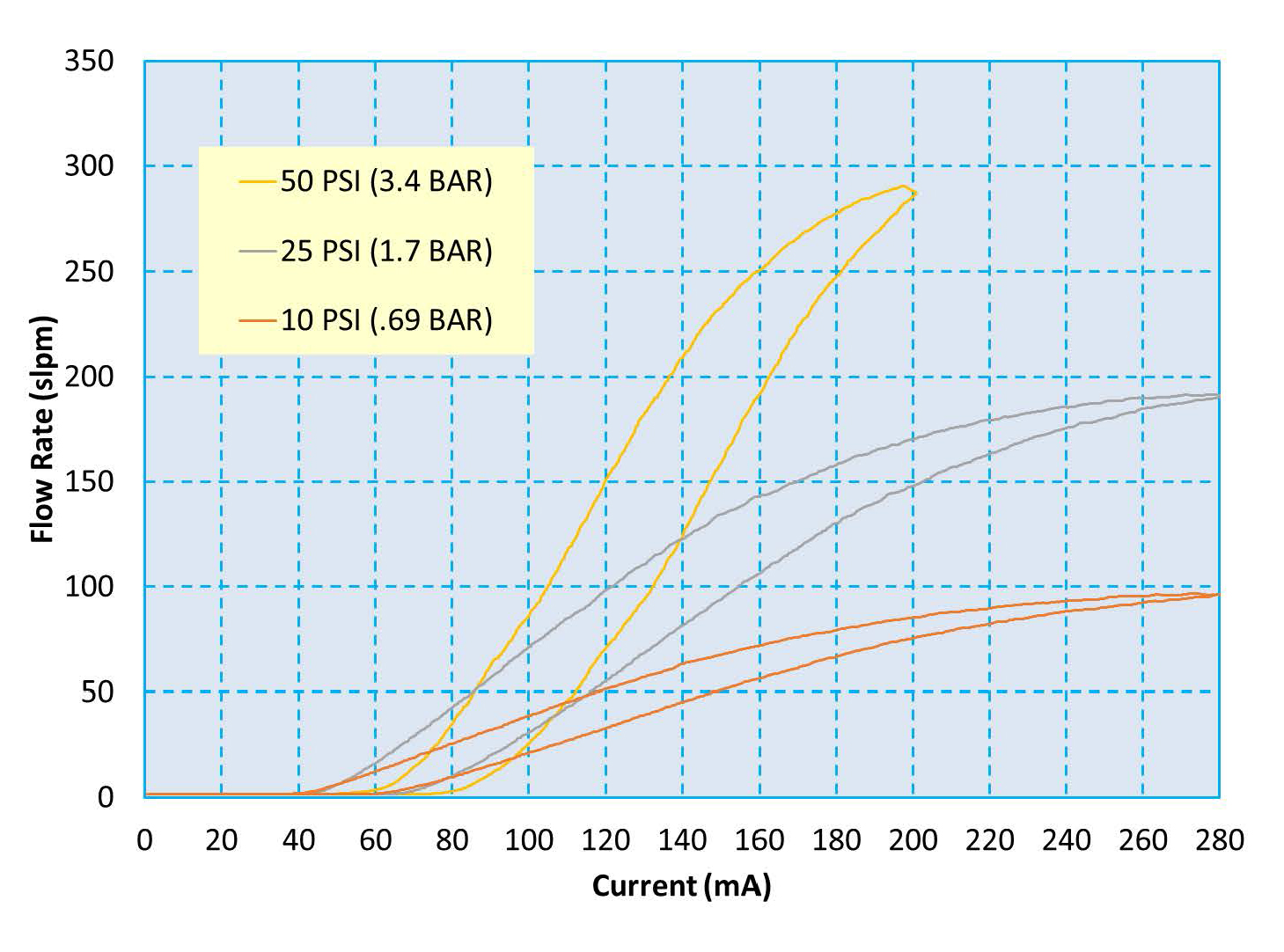

LM-Pro Model 4*

Typical Air Flow with 12 VDC Coil

*During operation at 50psi, a flow shift of up to 5% over the life of the valve may occur.

With a linear controllable flow range up to 540 slpm, pressure capability up to 100PSI (6.9 Bar), and typical power consumption of less than 2 Watts, the LM-Pro is a true,one-size-fits-all proportional valve

- Basic Control: The Parker LM-Pro valve can be controlled by either voltage or current; however, it is highly recommended that current control be employed to ensure the most repeatable valve flow performance.

- PWM Control: For PWM control, the signal applied to the valve should have a frequency of 5 kHz or greater. Optimum frequency will be application dependent.

Parker Precision Fluidics - Quick Links

Parker Precision Fluidics

26 Clinton Drive, Unit 103

Hollis, NH 03049

Ph: 603-595-1500

©Parker Hannifin 2021